Cost-efficient process route and increased plant availability

PJSC ArcelorMittal Kryvyi Rih, Ukraine, has awarded SMS group (www.sms-group.com) the contract to supply two secondary metallurgy plants and two six-strand continuous billet casters (Nos. 2 and 3). The new plants will be installed next to the existing caster No. 1 at Kryvyi Rih. With the new process route in place, more construction steel billets will be continuously cast at this site, gradually replacing ingot casting. It is planned to produce 2.8 million tons per year of quality billets.

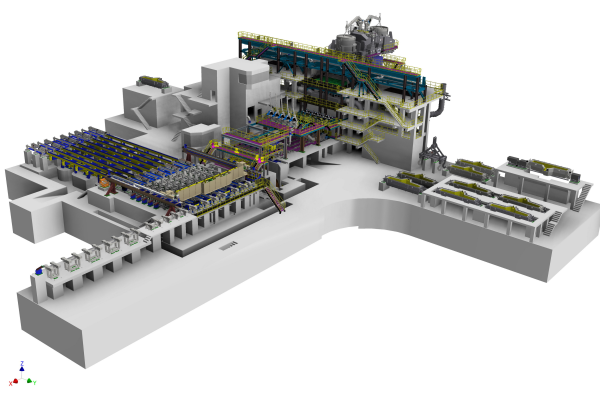

The scope of supply of SMS group S.p.A. will include two twin-ladle furnaces with a capacity of 160 tons each, a water treatment plant, a material handling system and a fume treatment plant. SMS Concast, an SMS group company, will supply two six-strand continuous billet casting plants. The material flow between the six existing BOF converters and the new plants will be visualized in advance using a powerful logistics simulation tool to ensure optimum productivity levels and prevent any bottlenecks.

SMS group offers a cost-efficient process solution that ensures both high plant availability and a quick return on investment. By changing the process route to continuous casting, with its increased yield ratio and significant energy savings, the plant will be capable of producing higher-quality billets at a lower cost. Final commissioning of all the equipment supplied by SMS group is scheduled for the first quarter of 2019.