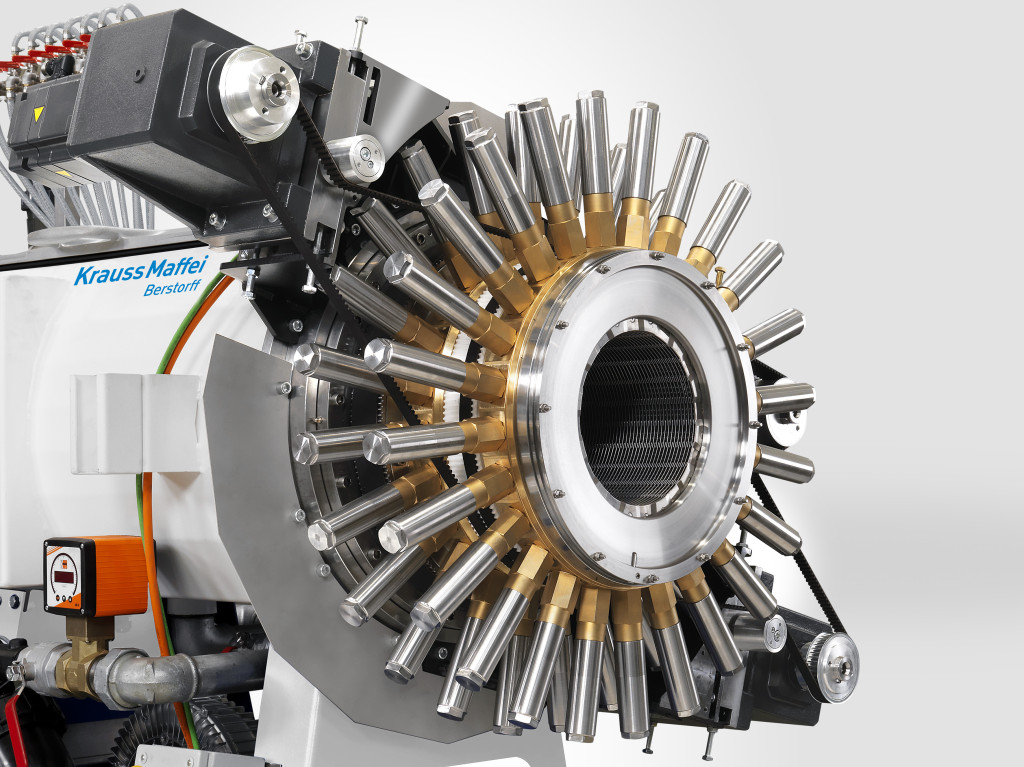

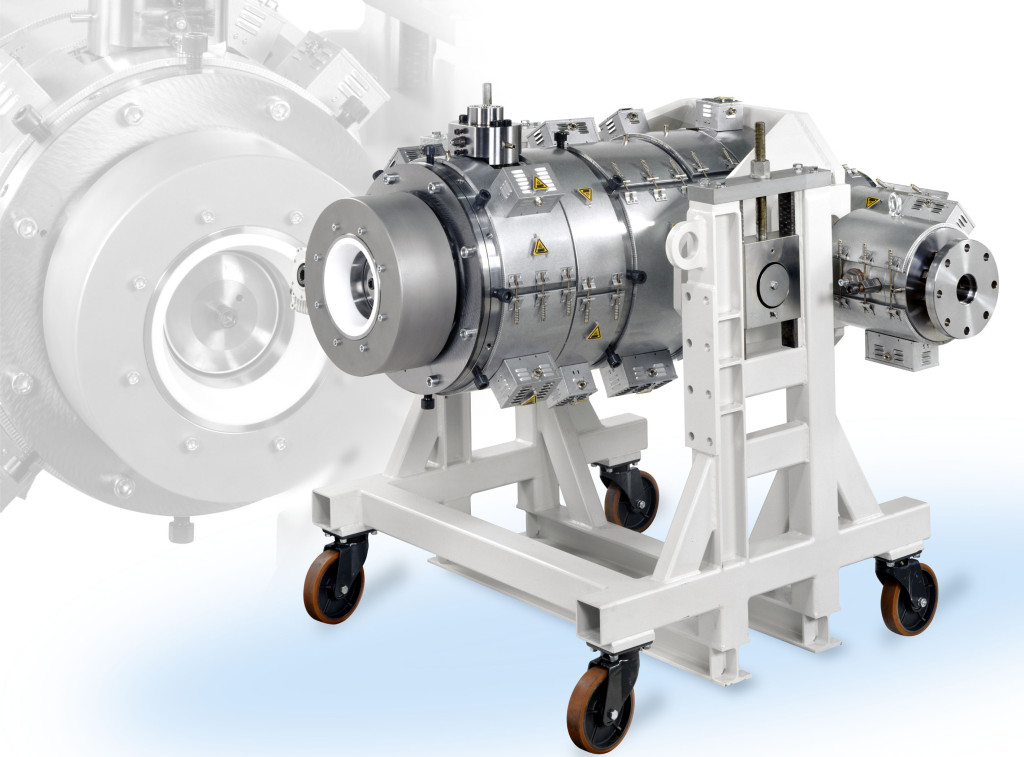

– Efficiently manufacture multi-functional pipes with the KM-3L RKW 74-250 IPC multi-layer pipe head

The C6 control system was introduced for the first time at the K2013 trade show, but now KraussMaffei Berstorff is introducing it to the American market starting at the NPE. “This premium quality control system is an intelligent combination of proven elements and innovative software components,” explains Matthias Sieverding, Head of Extrusion Technology in the USA. “Our customers have responded very well, particularly to the possibility of fast and reliable access management through non-contact identification by means of RFID readers,” says Sieverding enthusiastically. “It can also easily be integrated into a central data acquisition system. If there is any disruption to production, parameters can be quickly adjusted and corresponding countermeasures can be introduced,” Sieverding adds. At the NPE, KraussMaffei Berstorff will show the mobile version.

“We are seeing an increased demand, particularly for solutions that can fit the term ‘smart pipe’,” Sieverding says. “With our spiral distributor pipe head, we are providing a very innovative, complex and flexible system, which the customer can use to produce according to requirements for a wide variety of applications. For example, our customers want to produce reinforced pipes with filled intermediate layers to save on material costs. But pipes with a durable inner layer are also increasingly in demand, for example, for drinking water applications with a high amount of chlorine additive. In addition, the concept—a combination of radial and helical coils—guarantees precise production of thin films at a minimum wall thickness tolerance.” The KM-3L RKW 74-250 IPC exhibit is equipped with the efficient internal pipe cooling system, which, in addition to conventional external cooling, also cools the pipe from inside. By doing this, the processor can increase the output by up to 60 percent or, alternatively, reduce the cooling section by up to 40 percent.

The QuickSwitch system for in-line dimension change at the touch of a button is quite popular because it reduces production and material costs while increasing the delivery availability. “Following the high sales successes in Europe, we are seeing a growing trend toward new investments in complete lines in the USA,” Sieverding says. “Our technology provides enormous potential savings, such as lower standstill and changeover times, lower material costs, low capital lock-up and high delivery availability, even for small lot sizes.”

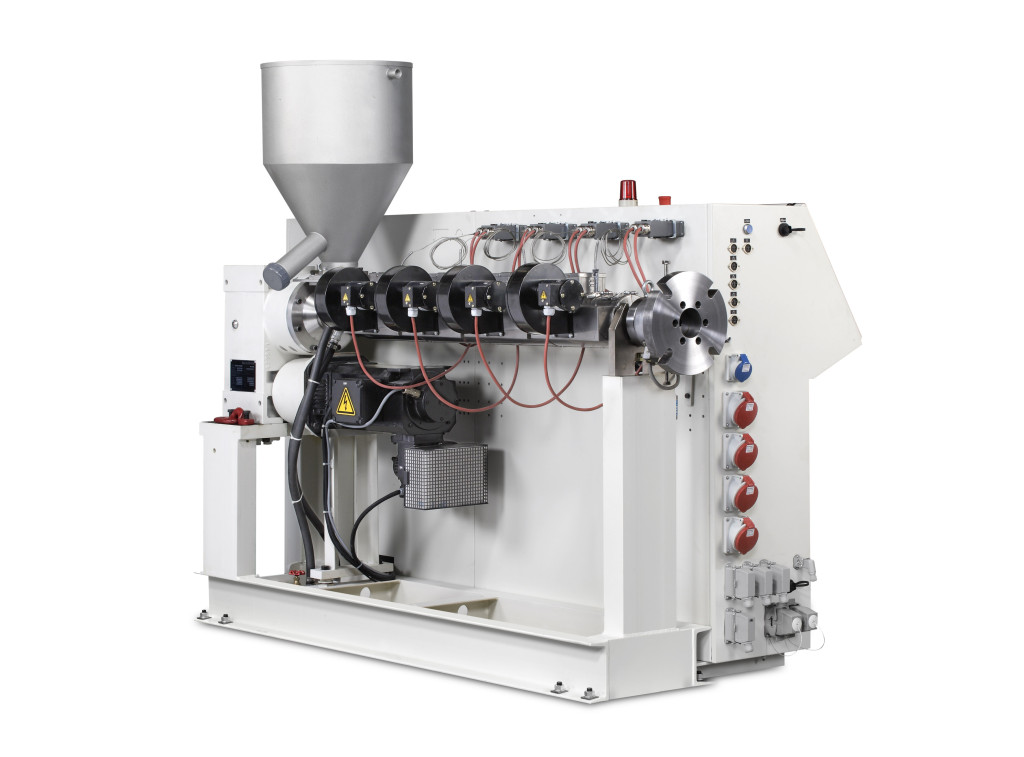

The KME 60 XS exhibit from the XS series stands as an example of how special materials such as TPE, TPU and POM are processed for manufacturing technical profiles. The machine, which was originally designed for standard pipe applications, can be optimally used specifically for small outputs, which are often desired particularly for manufacturing technical profiles.Further information to NPE at: http://npe.kraussmaffeigroup.com

About KraussMaffei Berstorff

Around the world, the KraussMaffei Berstorff product brand stands for advanced, futureproof extrusion solutions. The company’s product spectrum ranges from single extruders with application-specific tooling, to up- and downstream components and fully automated extrusion lines. This product range, plus a customer-specific choice of service modules, guarantee that KraussMaffei Berstorff is a robust system partner for customers such as the bulk chemicals, automotive, construction, packaging and pharmaceuticals industries. KraussMaffei Berstorff, part of the KraussMaffei Group since 2007, was created through a merger of KraussMaffei and Berstorff, an engineering specialist with a long tradition.For more information: www.kraussmaffeiberstorff.com

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com