|

– French Texen Group switches to KraussMaffei

– CX 160 with very extensive equipment and automation – Product development for cosmetic packaging |

|

(Munich, June 17, 2014) The Texen Group (Groupe Texen), one of the largest global manufacturers of plastic packaging for cosmetic and perfume products, recently commissioned a KraussMaffei injection molding machine for a wide range of technologies. This multi-component machine from the CX series is equipped with many refined procedural and mechanical features, which increase its flexibility in the development of injection molded packaging.

|

|

KraussMaffei impresses Texen with innovative ability

KraussMaffei received a milestone order in the French market. One of the leading international manufacturers of plastic cosmetic packaging recently started producing innovative plastic packaging for premium quality cosmetics and perfume using a CXZ 160 – 380/180 hybrid. With sales of nearly 170 million euros in the last fiscal year and almost 1,000 employees, Groupe Texen is one of the major companies in this market segment. The company manufactures injection-molded plastic packaging and screw-cap closures at eight locations in Europe, North America and Latin America. “Texen was looking for a partner who could deliver an injection molding machine with outstanding application flexibility.” In this respect, the requirements of the performance specifications were extremely demanding. “We have integrated all kinds of process engineering, which likely cannot be found in France or even in the market as a whole in this form,” explains Jacques Socquet, President of the subsidiary of the KraussMaffei Group in France. CX machine with extensive equipment and automation

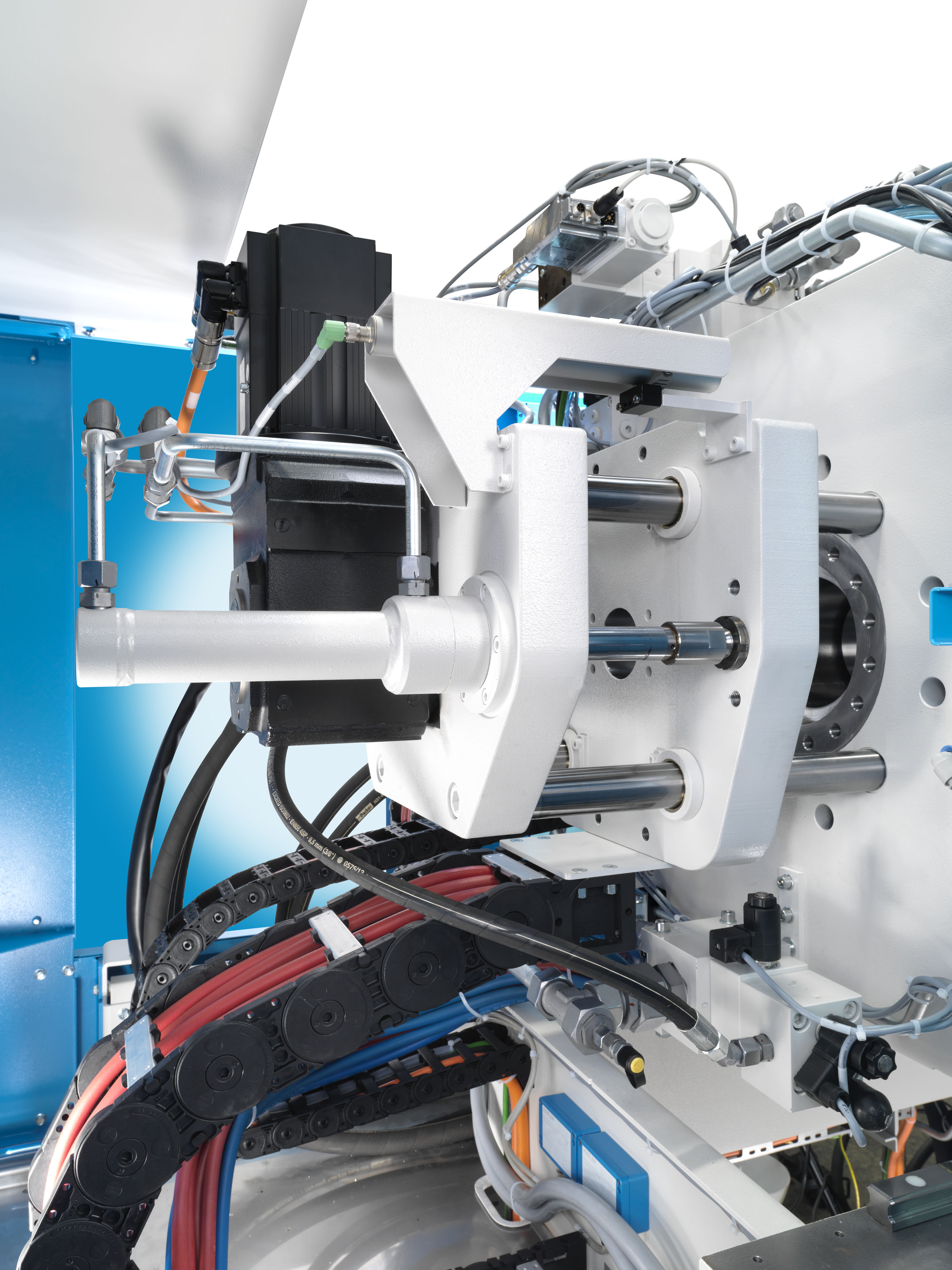

Texen opted for a two-component injection molding machine from the CX series, a CXZ 160 – 380/180, with a LRX 100 side-entry robot, a decision which resulted from constructive discussions with KraussMaffei sales, product and process experts from France and Germany. Fabrice Baravaglio, President of Texen, adds: “As a part of our strategy program “Ambition 2020”, PSB Industries, the parent company of Texen, is focusing on the expansion of R&D activities. The new innovation center “Texen Lab” was also established within this framework. Our new injection molding machine is utilized specifically for development projects. We envisioned a single machine that could map all of our requirements. KraussMaffei succeeded in making our vision a reality.” Consequently, Texen acquired a CX Hybrid with 1,600 kN of clamping force featuring an extensive equipment package. The CX Hybrid series combines the benefits of a fully hydraulic clamping unit with those of electrically driven injection units. This series is characterized by low energy consumption and high power density. Each shaft of the injection unit is electrically driven separately so that the mold can be opened and the ejector activated, even during the plasticizing phase. Shot weights up to about 140 g of polystyrene can be produced with the large injection unit. The machine is also designed for the injection of multi-component parts using a sandwiching technique and is equipped for molds in index implementation. Furthermore, physical foaming (MuCell) is possible with all components. It also comes equipped with control system interfaces for essential processes for achieving high-end surfaces, such as in-mold decoration, SkinForm/ColorForm, DecoForm or Coverform. The Dynamic Mold Heating (DMH) system from KraussMaffei is an integral part of these technologies. It separates the temperature control circuits in molds and creates a dynamic temperature profile in the mold. This innovation minimizes the masses in need of heat-balancing in the mold-halves and does not allow the mixing of the heating fluid with the coolant, which ensures effective operation of the system. Furthermore, the machine is equipped with interfaces for gas injection technology and the processing of liquid silicone (LSR). |

|

About KraussMaffei |

|

About the KraussMaffei Group

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com |