(Munich, April 21, 2015) As a system provider for complete solutions, KraussMaffei Berstorff is participating in the positive development of the pelletizing market. Thus, in the first quarter of 2015, multiple systems were delivered to Asia.

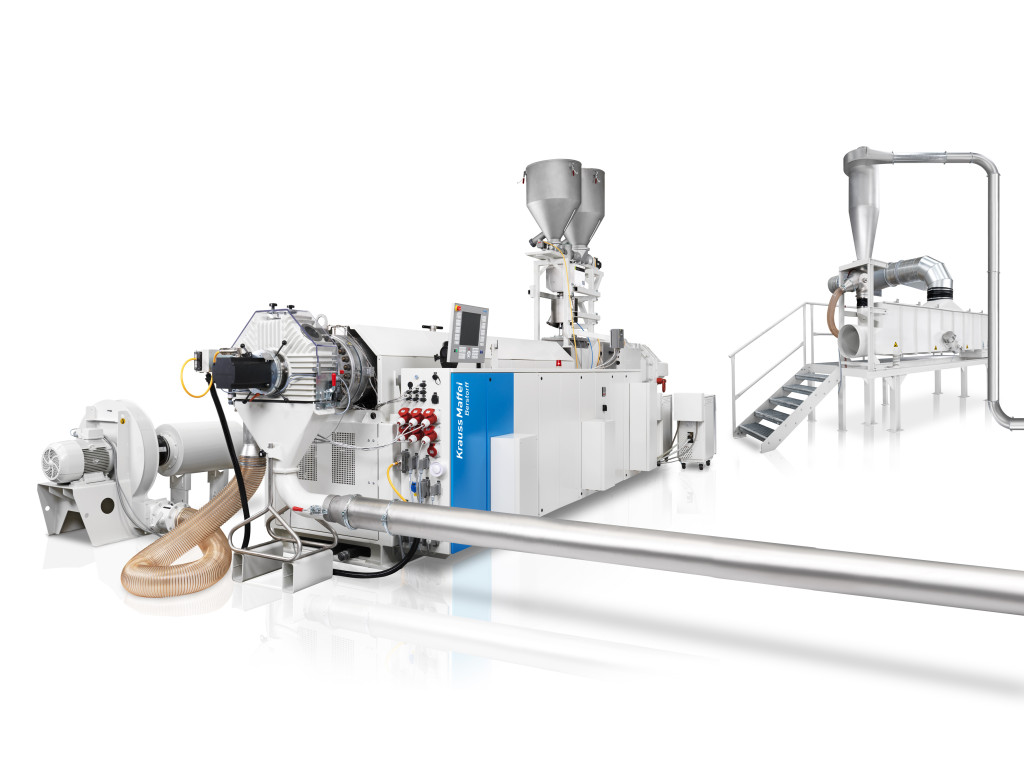

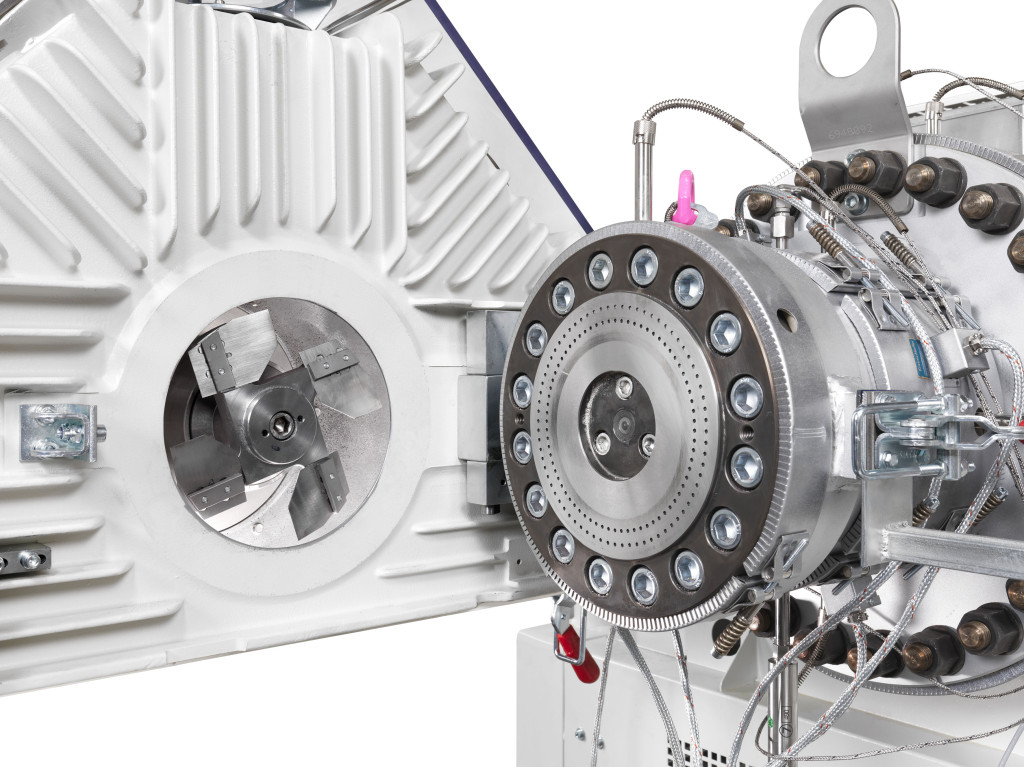

(Munich, April 21, 2015) As a system provider for complete solutions, KraussMaffei Berstorff is participating in the positive development of the pelletizing market. Thus, in the first quarter of 2015, multiple systems were delivered to Asia.“Currently we are seeing an increased demand for systems that process polyethylene with color masterbatch,” explains Andreas Kessler, General Sales Manager of KraussMaffei Berstorff at the Munich location. “But in addition, we are particularly happy about the good situation for orders of systems that pelletize rigid PVC, because here we are impressing customers with our longtime expertise as a system provider of complete systems that are exactly designed to meet their requirements—from the metering to the finished product,” Kessler says. “Thanks to their processing units matched to specific products, our twin-screw extruders feature very high outputs and excellent product quality.” The processor also benefits from the advantages of a cost-effective air-cooled pelletizer that is easy to operate, fast and easy to clean, and prevents pellets from sticking together.

“We are enjoying great competitive advantages because we are able to offer our customers comprehensive process-engineering expertise for processing a great variety of formulations,” Kessler adds. “As a result, we recently further developed and optimized our machine technology for processing C-PVC formulations.”

Particularly in Asia and India, KraussMaffei Berstorff sees great market potential for C-PVC pellets, which—when processed into fittings—are used in hot and cold water applications.

About KraussMaffei Berstorff

Around the world, the KraussMaffei Berstorff product brand stands for advanced, futureproof extrusion solutions. The company’s product spectrum ranges from single extruders with application-specific tooling, to up- and downstream components and fully automated extrusion lines. This product range, plus a customer-specific choice of service modules, guarantee that KraussMaffei Berstorff is a robust system partner for customers such as the bulk chemicals, automotive, construction, packaging and pharmaceuticals industries. KraussMaffei Berstorff, part of the KraussMaffei Group since 2007, was created through a merger of KraussMaffei and Berstorff, an engineering specialist with a long tradition.For more information: www.kraussmaffeiberstorff.com

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com