A focus on zero-defect production

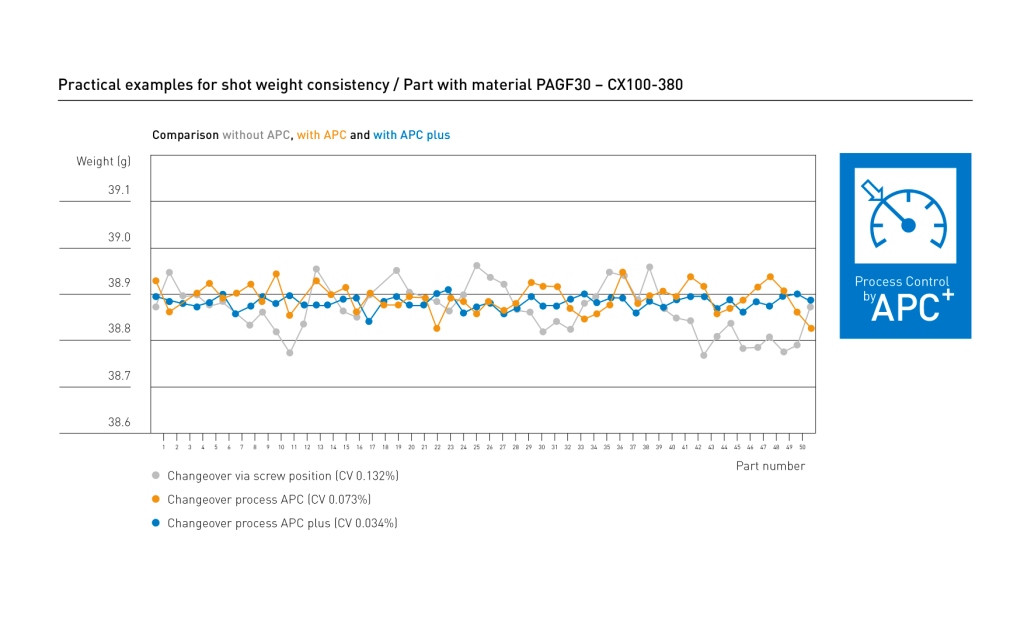

“The new APC plus now makes it possible to compensate for troublesome fluctuations in the manufacturing process during injection molding even faster and with greater precision. Our customers profit from exceptionally high precision and consistently high component quality,” explains Dr. Reinhard Schiffers, Head of Machine Technology at KraussMaffei. APC plus is able to learn even better than the APC machine function introduced on the market to great success in 2014. It offers even greater precision in detecting process fluctuations triggered by changing ambient conditions, such as temperature or humidity, caused by fluctuating viscosity and due to other factors. And it automatically takes measures to counter the fluctuations.

In the new APC plus, the user can choose from 20 basic materials plus filler types in a drop-down menu, thus taking into account the specific properties of the target material. “This makes the injection molding machine capable of, for the first time, responding to faults based specifically on the material and taking corrective action in the holding pressure phase,” says Schiffers. APC plus also takes the pressure-dependent compressibility of the melt into account to enable action with even greater precision and knowledge of the results. The compressibility provides information about how much melt has been introduced into the cavity. In addition, the closing behavior of the nonreturn valve can be predicted with even greater precision thanks to an optimized algorithm, making it possible to determine the ideal changeover point.

Ideal for cascade injection molding

The new APC plus function is, like its predecessor, ideal for processing thermoplastics, multi-component injection molding or processing silicone. In addition, it provides perfect component quality even for special applications, such as cascade injection molding. In this process, the times when the needle seal nozzles open are adapted so that they always open at the same mold fill level, regardless of the viscosity present in the current shot. APC plus is offered on all-electric and hydraulic series from KraussMaffei.

Part of Industry 4.0

The new APC plus machine function is an important part of the Plastics 4.0 strategy that KraussMaffei uses to bundle its activities for implementing the vision of Industry 4.0. Plastics 4.0 is divided into three subareas: intelligent machines, interactive production and intelligent services. APC plus embodies the idea of intelligent machines, a concept that refers to intelligent, self-optimizing machines which improve productivity and quality.

KraussMaffei is supporting the “K 2016: The Kountdown has begun!” video series initiated by the VDMA Plastics and Rubber Machinery Association together with Plas.TV. These videos are designed to let viewers experience Industry 4.0 using specific, real-world examples. KraussMaffei’s contribution can be found at https://player.vimeo.com/video/183788942.

KraussMaffei at K 2016

Hall 15, Booth B27/C24/C27/D24